Refining Ideas.

The heater has gone out in the shop, impeding any real progress on anything real happening out there. Add to that finishing up with the final big projects to help my brother and his family live comfortably in their new home and I haven't had a whole lot to record here at all. But the weather broke earlier in the week with some temps above freezing and I managed to steal a couple hours in the shop.

I installed a couple new shop lights, now I have all my major work areas well illuminated. This is a good thing. I managed to organize and put away the tools and tool boxes I had hauled out to help at my brother's. I also managed to shuffle around my accumulated stock in search of something appropriate to use in the upcoming Shop Stool Build Off.

I had plenty of white oak in piles, but some of it is already spoken for in other projects. None of it was as thick as I remembered. I thought I had some 8/4 stock, but it all turned out to be 5/4. This realization pushed a couple decisions.

The thickness of stock tells me I have to laminate pieces together to get what I want out of it. The project is a fun, one day diversion. But I don't want to buy special lumber for it, I want to use up some of what I've stockpiled. I took the rest of the day to rough out and laminate glue together the stock for the four legs and the seat. I know the build off is supposed to be a one day only build, but I couldn't afford to do this on the day of and wait for the glue to set on all the major pieces.

If those participating deem this foul play, then I will have to live with that sentence and consider myself disqualified. That will not stop my participation on the 25th.

***

The stock I decided to use also wasn't wide enough to cut a suitable round blank from. The original plan I had for the seat.

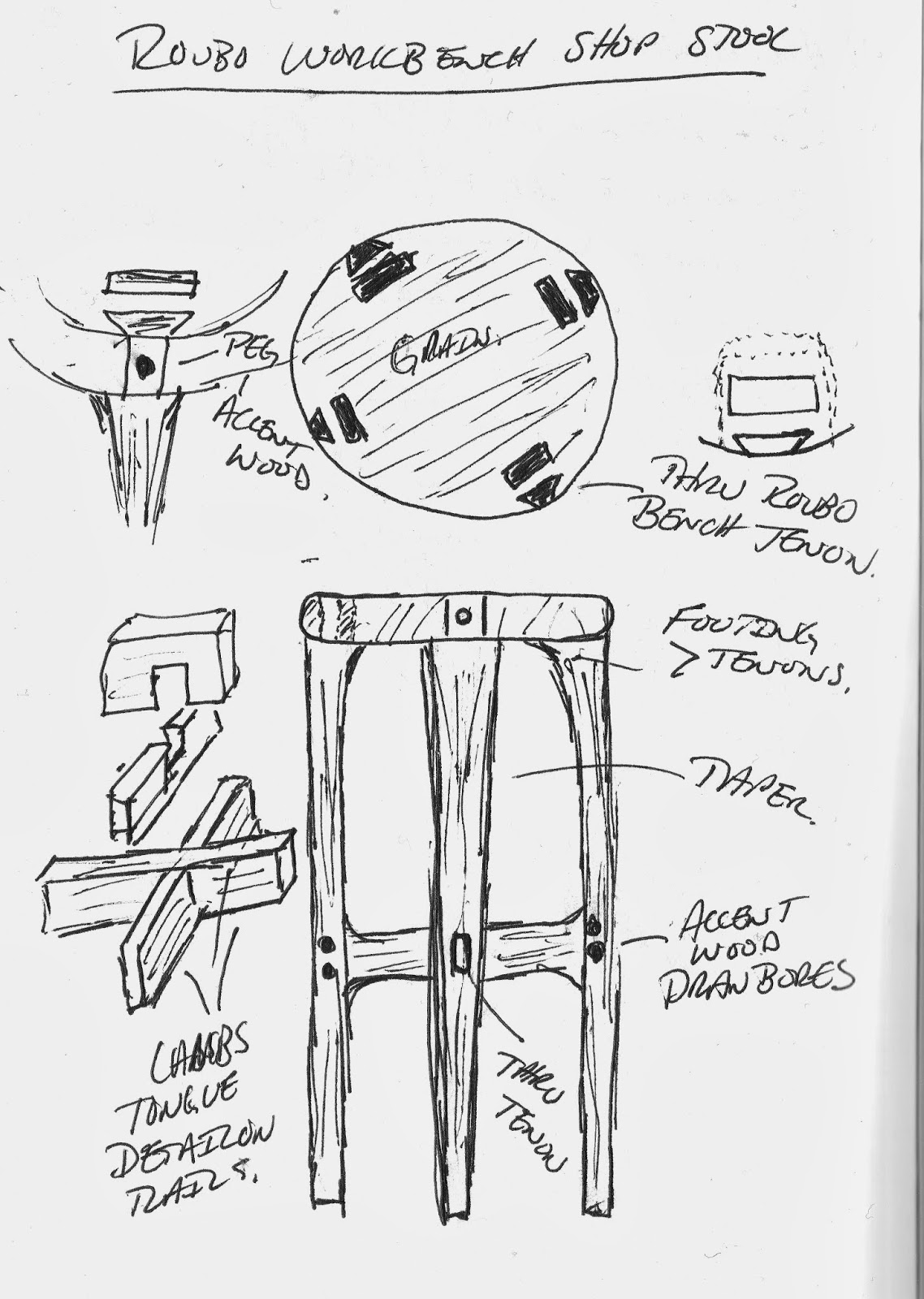

So I modified my attack to be a little closer to the look of the Roubo Plate 11 bench itself.

Here's the measured drawing I completed earlier this morning to check my proportions and spacing. Going with a rectangular seat (similar to the seat on my current shop stool) also removes the design issue I was having with the crossing stretchers. It's a bit stiffer and more formal in shape but I think I can help that with some sculpting of the seat, legs, and stretchers. I wish I had the time to laminate another section to the top and make it thicker yet, but I figure I had better leave well enough alone.

I do like adding the details of the holdfast holes in the legs. I'm not sure they'll be truly functional with the length of my Gramercy Holdfasts. We will see in time but that would be such a bonus.

It's an ambitious project to pull off in a one day build, I think it's do able, but it will be a long day. To keep myself on track and task I wrote out a step by step list to follow. Thirty One steps seems like a lot, and maybe it is. But you don't know how much you can accomplish until you try. I've been kind of big on testing myself lately to find the limits.

I think that's why this build off appealed to me so much.

(I know it stops at 29, but you'll also notice there's a, 11.5 and a 17.5. and just now as I'm writing this I thought of a 26.5 "Level the Legs" so that makes 32 steps)

Ratione et Passionis

Oldwolf

If you haven't signed up to be part of the Shop Stool Build Off to be held on January 25th and think you may be interested, head over to visit the mastermind Chris Wong from Flair Woodworks and learn more. The link to the Build Off page is here

http://flairwoodworks.com/shop-stool-build-off/

I can't wait to see what everyone else comes up with.

D

I installed a couple new shop lights, now I have all my major work areas well illuminated. This is a good thing. I managed to organize and put away the tools and tool boxes I had hauled out to help at my brother's. I also managed to shuffle around my accumulated stock in search of something appropriate to use in the upcoming Shop Stool Build Off.

I had plenty of white oak in piles, but some of it is already spoken for in other projects. None of it was as thick as I remembered. I thought I had some 8/4 stock, but it all turned out to be 5/4. This realization pushed a couple decisions.

The thickness of stock tells me I have to laminate pieces together to get what I want out of it. The project is a fun, one day diversion. But I don't want to buy special lumber for it, I want to use up some of what I've stockpiled. I took the rest of the day to rough out and laminate glue together the stock for the four legs and the seat. I know the build off is supposed to be a one day only build, but I couldn't afford to do this on the day of and wait for the glue to set on all the major pieces.

If those participating deem this foul play, then I will have to live with that sentence and consider myself disqualified. That will not stop my participation on the 25th.

***

The stock I decided to use also wasn't wide enough to cut a suitable round blank from. The original plan I had for the seat.

So I modified my attack to be a little closer to the look of the Roubo Plate 11 bench itself.

Here's the measured drawing I completed earlier this morning to check my proportions and spacing. Going with a rectangular seat (similar to the seat on my current shop stool) also removes the design issue I was having with the crossing stretchers. It's a bit stiffer and more formal in shape but I think I can help that with some sculpting of the seat, legs, and stretchers. I wish I had the time to laminate another section to the top and make it thicker yet, but I figure I had better leave well enough alone.

I do like adding the details of the holdfast holes in the legs. I'm not sure they'll be truly functional with the length of my Gramercy Holdfasts. We will see in time but that would be such a bonus.

It's an ambitious project to pull off in a one day build, I think it's do able, but it will be a long day. To keep myself on track and task I wrote out a step by step list to follow. Thirty One steps seems like a lot, and maybe it is. But you don't know how much you can accomplish until you try. I've been kind of big on testing myself lately to find the limits.

I think that's why this build off appealed to me so much.

(I know it stops at 29, but you'll also notice there's a, 11.5 and a 17.5. and just now as I'm writing this I thought of a 26.5 "Level the Legs" so that makes 32 steps)

Ratione et Passionis

Oldwolf

If you haven't signed up to be part of the Shop Stool Build Off to be held on January 25th and think you may be interested, head over to visit the mastermind Chris Wong from Flair Woodworks and learn more. The link to the Build Off page is here

http://flairwoodworks.com/shop-stool-build-off/

I can't wait to see what everyone else comes up with.

D

.jpg)

Comments

Post a Comment